Complete design and manufacture of rubber & plastic production and prototype molds

Complete design and manufacture of rubber & plastic production and prototype molds

-

- Rubber – injection, compression and transfer molds

- From single cavity to 500+

- Rubber-to-metal bonded molds

- Plastic/TPE’s – small to medium-sized injection (20 to 250 ton range), 2D and 3D molds

- Mold materials – several options depending on the project

- A significant inventory of various mold blanks is kept to minimize tooling lead-times

Precision CNC machining of any kind, three-axis and five-axis

Precision CNC machining of any kind, three-axis and five-axis- EDM services including wire and sinker EDM. We often make electrodes and EDM for other tool makers

- Trim dies, check fixtures and part removal tools

- MIG and TIG welding for tooling repairs and modifications

- Rubber and plastic mold validation.

- Full support for tool transfers

- FaroArm measuring

- Grinding, lathe turning and gun drilling

- Building platens for rubber presses, rework and grinding

- Machining of cavity blocks, ejector plates and slides

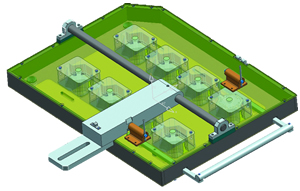

- Fabrication of rotating core bar frames and shuttling frames for rubber presses

- Loading and knock out boards

- In-house product design using NX